OUR SERVICES

Analysis

Safety & Efficiency in Every Step

Davies Engineering Group understands that safety is paramount. That’s why we offer a comprehensive range of analysis services to ensure your facility is running safely—and efficiently.

MEP Studies

The study of MEP systems covers a broad range of systems and needs. From understanding consumption and existing capacity, to planning for expansion and disaster recovery, every facility manager is tasked with having a deep understanding of their system’s capabilities and opportunities for improvement.

DEG’s long-standing expertise in analysis helps owners understand their historical, current, and projected needs. We tailor our approach to each client’s specific project needs to include customer financial criteria such as IRR, borrowing rates, and actual contracted energy costs, so you can make the best decision—whether you’re modeling lifecycle cost analysis or simply scaling projects for the best economic advantage.

Master Planning

Allow DEG to help you create a Master Plan with our straightforward yet thorough process. We begin by understanding the owner’s needs and goals, as well as the facility’s current condition. Then, we establish future strategies to achieve the goals. Below is an example of how our Master Planning process may flow.

| 1. Understand Owner Needs & Goals | 2. Understand Facility’s Current Condition | 3. Establish Future Strategies |

| Energy reduction & optimization | Interview associates to understand operation, including capabilities & shortfalls, efficiencies & inefficiencies | Project cost & construction phasing |

| Facility reliability | Determine facility energy usage via utility bills and on-site metering | Energy savings |

| System redundancy | Review facility operations and identify reliability and redundancy issues | Reliability & redundancy improvements |

| Future growth or reduction | Maintenance considerations |

Condition Assessments

As a key component of Master Planning, condition assessments provide critical insights into the current state of systems, helping owners make informed decisions about maintenance, upgrades, and long-term investments. These evaluations prioritize business continuity by identifying urgent spending needs while also guiding future capital planning for non-immediate concerns.

DEG conducts comprehensive condition assessments across utility, control, and process systems, analyzing key factors such as:

- System age & overall condition

- Manufacturer support status

- Risk of failure & potential impact

- Spare part availability

- Failure modes, associated risks, & potential challenges in restoring service

This proactive approach helps mitigate risks, optimize system reliability, and ensure uninterrupted operations.

Arc Flash

Have questions about arc flash studies, NFPA 70E, electrical system documentation, or protective device coordination? We’re here to help. Let’s talk about your current situation and work together to create an electrical safety plan that keeps your facility reliable and your employees safe.

What Is an Arc Flash?

An arc flash is a sudden burst of energy caused by an electrical fault. It happens when electricity jumps between conductors or from a conductor to the ground. This creates an extremely hot plasma that can reach 35,000°F—hotter than the surface of the sun. The result is a powerful explosion of heat, light, metal fragments, and pressure waves, which can cause serious burns, hearing loss, or even be fatal. Arc flashes can be triggered by faulty equipment, insulation failures, dust buildup, or tools accidentally touching live wires.

Why Does My Facility Need an Arc Flash Study?

To meet Occupational Safety and Health Administration (OSHA) safety rules, your facility must follow a six-step process:

- A facility must provide, and be able to demonstrate, a safety program with defined responsibilities.

- Calculations for the degree of arc flash hazard.

- Correct personal protective equipment (PPE) for workers.

- Training for workers on the hazards of arc flash.

- Appropriate tools for safe working.

- Warning labels on equipment. Note that the labels are provided by the equipment owners, not the manufacturers.

The National Fire Protection Association’s (NFPA) standard provides guidelines for a complete electrical safety program. While it’s not a legal requirement, following NFPA 70E ensures compliance with OSHA’s arc flash safety standards.

Benefits of an Arc Flash Study

- Ensuring compliance with OSHA workplace safety standards.

- Providing updated electrical system diagrams.

- Delivering a detailed arc flash study report.

- Labeling electrical equipment to help workers choose the right PPE.

- Suggesting improvements to make your electrical systems safer.

How an Arc Flash Study Works

- Collect Relevant Information

- Collect system and installation data.

- Field comparison of existing single-line diagrams against existing conditions, updating drawings as necessary.

- Analyze all equipment, collecting nameplate data, circuit breaker data and trip settings, physically verifying fuse types and ratings, and physically verifying feeder sizes.

- Determine the system’s normal and any secondary modes of operation, addressing alternate utility feeds, backup generators, etc. “Worst-case scenario” is always used for generating hazard data.

- Create Fault-Detection Software Model

- Use collected data to create a software model of electrical system, including modeling all wire sizes and lengths, fuses, circuit breakers, etc.

- With this model, we determine fault current at every key point in the electrical system in a number of fault scenarios to ensure all equipment is properly rated for that available fault current.

- Evaluate protective device coordination to ensure that in the case of a fault, the correct device will trip to minimize fault time.

- Run Arc Flash Calculations

- Determine the amount of Incident Energy generated during an arc event (calories/cm2).

- Determine the Approach Boundaries for qualified and nonqualified personal. This is determined by the Incident Energy value as well as the enclosure type.

- Determine the types of PPE required based upon the Incident Energy calculated.

- Finalization & Recommendations

- Generate and apply labels to provide trained personnel with all data necessary to work safely.

- Generate report with all results (fault current, coordination, arc flash calculations) and brief explanations, as well as recommendations to make the system safer if any problems are encountered.

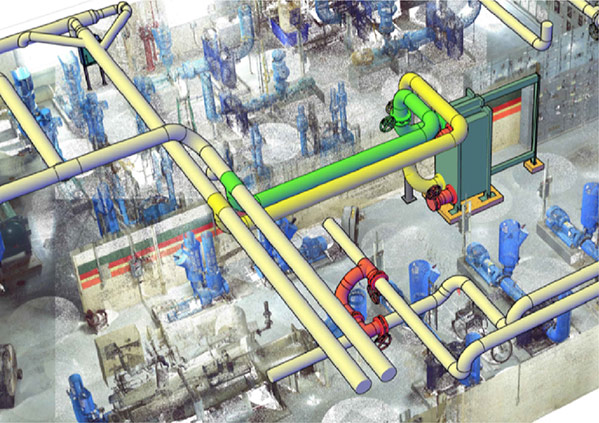

3D Scanning

With our 3D scanning technology, we can capture your space in detail, allowing us to view, navigate, and verify measurements from any computer—no need for extra site visits. This enhances our design and analysis work while saving you time and money.

With our 3D scanning technology, we can capture your space in detail, allowing us to view, navigate, and verify measurements from any computer—no need for extra site visits. This enhances our design and analysis work while saving you time and money.

The 3D Scanning Process

Our scanner uses a laser to collect data points by bouncing light off surfaces, and a built-in camera adds color to these points. We then combine multiple scans to create a full “point cloud” of your facility.

Why Use 3D Scanning?

The point cloud helps us verify dimensions, check clearances, and create precise drawings. While it doesn’t completely replace traditional fieldwork, it allows us to confirm measurements remotely. It also makes it easier to measure hard-to-reach areas, such as high ceilings and spaces above process lines.

What You Get From 3D Scanning

In addition to improving the design process, you’ll receive an accurate 3D model of your facility. The point cloud can be used in software like AutoCAD, and we can export it in a format that lets you view the scans without special software. You can also revisit the scans later to take measurements for future projects.